Ntau tus pib poob rau hauv qhov ntxiab thaum yuav cov xim coated yob vim lawv tsis nkag siab txog lawv cov khoom. Yog li, cov khoom siv dab tsi zoo rau cov xim coated yob?

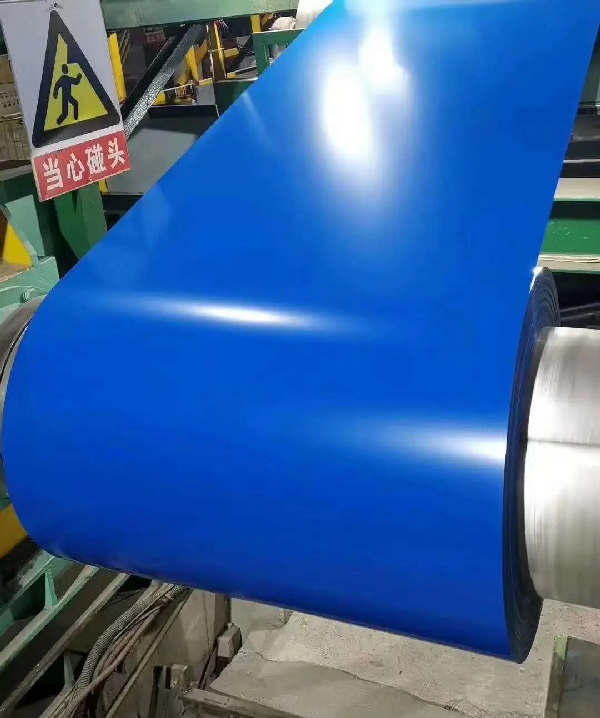

Lub substrate rau cov xim coated coils tuaj yeem yog txias-dov coils lossis kub-dip electroplated steel. Txawm hais tias cov txheej txheem organic ntawm cov xim coil muaj cov txiaj ntsig zoo los tiv thaiv corrosion, tseem muaj qee qhov khoob me me hauv cov txheej txheem organic, uas tuaj yeem ua rau huab cua thiab noo noo nkag mus thiab ua rau xeb ntawm cov substrate. Yog li ntawd, xim coated coils ua los ntawm uncoated substrates muaj ib tug luv luv kev pab cuam lub neej thiab yog nquag mus rau diffusion thiab txheej tev tawm tom qab khawb. Lub substrate ntawm cov xim coated steel kauj yog tsuas yog galvanized steel phaj los yog galvanized hlau alloy rau steel phaj technology. Hauv qee cov kab ntau lawm, cov txheej txheem ntau lawm ntawm cov xim txheej yog muab faib ua substrate pre-treatment, chemical conversion coatings (non organic metal coatings), organic non-metallic coatings, and post coating processes.

1 、 Kev kho substrate ua ntej: Yog tias peb tsis yog lub tuam txhab uas tuaj yeem nkag mus rau cov txheej txheem xim txheej ntawm tib neeg tom qab kev tsim khoom, galvanized steel daim hlau siv los ua cov substrates yuav tsis tu ncua muaj xeb (xeb dawb), plua plav, thiab lwm yam kev ua qias tuaj thaum thauj thiab kev loj hlob. . Yog tias cov no tsis tuaj yeem raug tshem tawm, qhov zoo ntawm cov xim yuav raug cuam tshuam. Qhov zoo ntawm cov xim coated rolls tiav thiab kev ua haujlwm ntawm lub cev thiab tshuaj lom neeg ntawm txhua tus tub ntxhais kawm muaj feem cuam tshuam nrog kev kho mob ua ntej. Tsis tas li ntawd, nyob rau hauv galvanizing ntau lawm, thiaj li yuav tiv thaiv xeb thiab oiling, cov roj no kuj raug tshem tawm ua ntej xim txheej ntau lawm. Txoj kev siv ua ntej siv tam sim no yog alkaline kua degreasing txoj kev.

2 、 Cov tshuaj hloov dua siab tshiab zaj duab xis muaj ob txoj haujlwm

Ib qho yog txhawm rau txhim kho kev tiv thaiv xeb ntxiv,

Qhov thib ob yog txhawm rau txhim kho qhov adhesion ntawm substrate thiab txheej txheej, thiab txhim kho cov txheej txheem txheej txheem ntawm substrate.

Feem ntau muaj peb kauj ruam:

Ib qho yog phosphating, uas thawj zaug tsim muaj ntau cov muaju ntawm cov hlau nto, thiab tom qab ntawd tsim ib txheej ntawm phosphate zaj duab xis ntawm cov hlau nto nrog phosphate ntsev tov;

Qhov thib ob yog passivation thiab sealing. Cov phosphate zaj duab xis tseem muaj qee qhov pores, uas yog tshuaj lom neeg nrog chromates los tsim cov yeeb yaj kiab tiv thaiv. Thirdly, ntxuav nrog dej ntshiab thiab tshem tawm cov tshuaj passivation nrog desalinated los yog deionized dej.

3 、 Organic coatings feem ntau muab faib ua primer thiab topcoat. Cov kev cai primer tsis siab thiab tuaj yeem siv rau hauv cov xim zoo nkauj. Txawm li cas los xij, txhawm rau txhim kho cov ntaub ntawv kev ruaj ntseg, Suav cov lag luam feem ntau siv cov xim rov qab txheej txheej rau primer thiab topcoat.

Cov txheej txheem tom qab txheej txheej: Cov txheej txheem tom qab txheej txheem suav nrog kev luam ntawv, embossing, tev tawm cov yeeb yaj kiab tiv thaiv, kev sib txuas, thiab lwm yam, uas txhim kho cov hniav zoo nkauj thiab kev tiv thaiv ntawm cov xim coated board.

Post lub sij hawm: May-31-2024